Furnace Seal / Purge

This device design effort was part of an overall project to design an annealing line for a medical device wire manufacturer that would provide cleaning, annealing, quenching and gauging capabilities. This was as a result of growing product demand, for which the company had a need to scale up from their prototype manufacturing line with one that would yield higher throughput and tighter process control.

Challenge

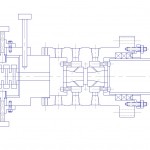

In order to prevent oxidation of a nickel-titanium alloy during the high-temperature annealing step, an inert atmosphere was required within a quartz tube furnace through which the wire would continuously pass. Though tube furnaces are readily available, custom purge/sealing devices were needed to control the furnace atmosphere and minimize gas losses yet tailored to the scale and geometry of the furnace.

Solution

• developed an approach for the end-mounted furnace purge-seals

• created a 2-D CAD model of the proposed hardware

• presented the approach, then CAD modeled the components

• obtained quotations and identified vendors to machine and build the stations

• created a 2-D CAD model of the proposed hardware

• presented the approach, then CAD modeled the components

• obtained quotations and identified vendors to machine and build the stations

Services/Skills

• 3-D CAD modeling

• Mechanical Engineering

• Mechanical Design

• Mechanical Engineering

• Mechanical Design

Results

The design of this device was delivered along with a cost basis and manufacturing recommendations which enabled the client to proceed with manufacturing expansion plan.

Additional Project Images